A sufficient guidance about maintenance for RPX

Confirm the following inspection items before operation and at the time of change in work shifts:

-

-

There is no approach route to the dangerous part of the machine with the exception of the detection area of the RPZ.

-

When working in the dangerous part of the machine, part of the body remains in the detection area of the RPZ.

-

The measured value of the safety distance is greater than the calculated value.

-

The optical surfaces of the emitter an d receiver are not dirty and damaged.

- The detectable object for inspection is not deformed.

-

Turn on the power supply to the RPZ with nothing existing in the detection area.The power indicating lamp and ON output indicating lamp go on within 2 seconds after power up.

-

When the test piece is made to move in the detection area as shown below, the test rod can be detected. That is, when the test rod enters the detection area, all of the 5 light receive level indicating lamps go off and the OFF output indicating lamp goes on.

Bring the machine into the operating state and confirm the stop of the dangerous part as follows:

Bring the machine into the operating state and confirm the stop of the dangerous part as follows: -

The dangerous part is in the operating state with nothing existing in the detection area.

-

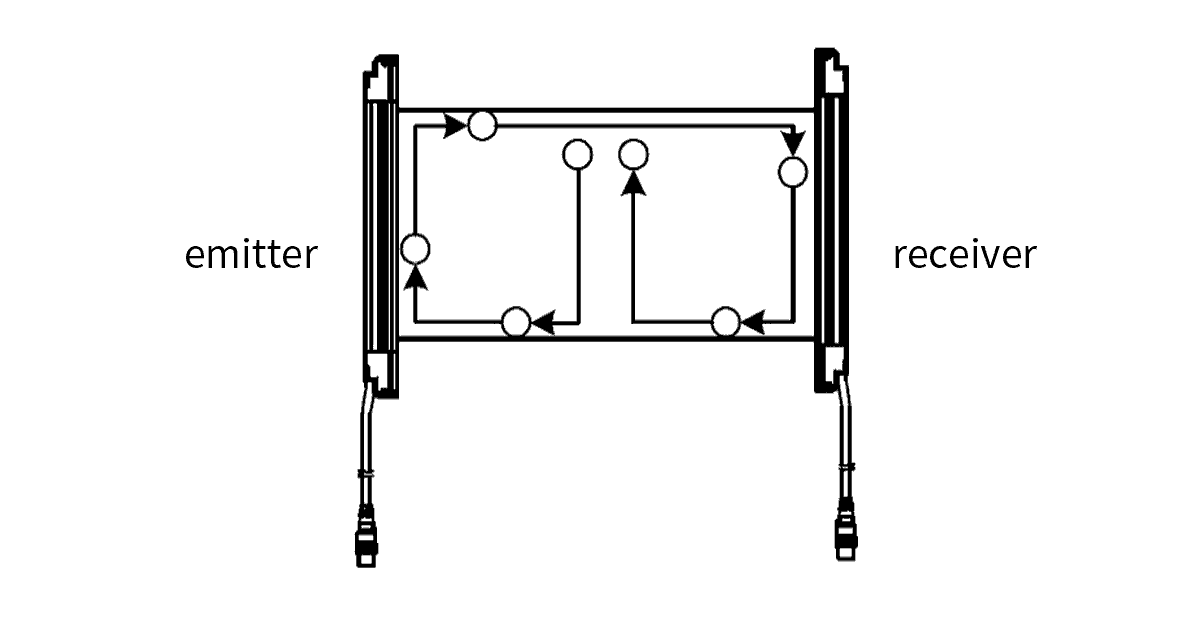

When the test piece is made to enter the detection area at three places “right before emitter,” “right before receiver” and “middle between emitter and receiver,” the dangerous part stops at once (use the correct test piece).

-

The dangerous part continues stopping as far as the detectable body for inspection exists in the detection area.

-

Turn off the power supply to the RPZ with nothing existing in the detection area and the dangerous part stops.

-

Semi-annual inspection

Confirm the following inspection items every six months and when the machine settings are altered:

-

The machine itself is designed not to in terfere with the safety function such as stopping.

-

Modifications and connection changes that adversely affect the control system of the machine have not been made.

- The output of the RPZ and the machine are correctly wired.

-

The actual response time of the machine as a whole is less than the calculated value.

-

The switching frequency of the relay is su fficiently is sufficiently low with respect to the lifetime switching frequency.

- The tightening screws of fittings are not loose.

- There is no ambient light.