RIKEN OPTECH’s vision is to be an enterprise, which contributes to customers and society in the fields of safety, health and hygiene. We also aim to keep challenging the boundaries of creativity and innovation.

Business Fields

Protection for the eyes and face

Products to support a high level of safety from all points of view

To create products like protective glasses and goggles, welding glasses, face shields used in the working environment, we try to put ourselves in the position of the workers. We developed our own anti-mist technology called VF Coating, so that workers can be comfortable while using a variety of different products.

In addition, filters to protect the eyes from light rays harmful to the body such as those from laser machines are produced to accommodate various specifications of laser. We also organize safety courses for customers to increase safety awareness. Throughout our development activity we listen to our customers’ requirements, as we develop our products.

We pay careful attention to the valuable contributions from our customers in our product development process. We make daily efforts to ensure that these products are more trusted and able to be used safely and with confidence, so that we can grow as our customers grow.

Safety devices for presses and other peripheral equipment

Developing new possibilities through the application of safety technology

The main function of our safety equipment for press machines and press brakes is to create safe conditions for workers operating the machines, and over many years we have accumulated experience and achievements, which support our reputation in this field today. We employ a variety of laser types and bypass functions to achieve this. The various models we produce aim to work successfully but also to be comfortable to use.

In addition our load monitors, malfunction detectors and die monitoring systems support quality control and equipment maintenance. The majority of these products are manufactured in-house, so we are actually developing, manufacturing, selling and providing after care, so that our customers can be comfortable using our machines.

Furthermore we meet international standards enabling us to build an overseas network, which is turning us into a global company.

Company Outline

| Company Name | RIKEN OPTECH CORPORATION |

|---|---|

| Head Office | 2-6-9 Higashi Ohi, Shinagawa-ku, Tokyo 140-8533 JAPAN |

| Establishment | 29 May, 1950 |

| Capital | 100,000,000 JPY |

| President and CEO | Maiko Misu, President |

| Main Banks | MUFG Bank, Ltd. Mizuho Bank |

| Trade Memberships | Japan Industrial Safety and Health Assosciation Technology Institution of Industrial Safety Japan Safety Appliances Association Japan Construction Occupational Safety and Health Association Japan Press Safety Devices Association |

History

| 1950 |

|

|---|---|

| 1953 |

|

| 1955 |

|

| 1956 |

|

| 1960 |

|

| 1962 |

|

| 1967 |

|

| 1972 |

|

| 1976 |

|

| 1978 |

|

| 1981 |

|

| 1985 |

|

| 1987 |

|

| 2002 |

|

| 2007 |

|

| 2008 |

|

| 2011 |

|

| 2013 |

|

| 2015 |

|

| 2018 |

|

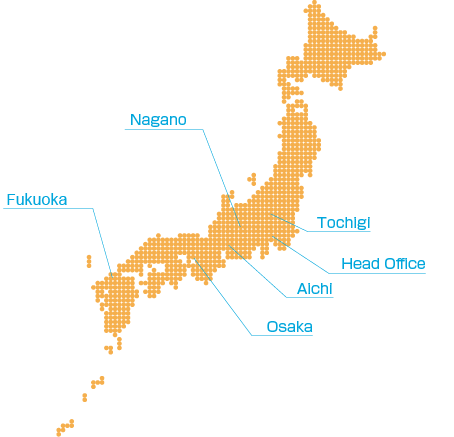

Business Locations

| Head Office | 2-6-9 Higashi ohi, Shinagawa-ku, Tokyo 140-8533 JAPAN |

|---|---|

| Tochigi | 943 Shimokanai-cho, Utsunomiya-shi, Tochigi 321-2114 JAPAN |

| Nagano | 5615-1 Taguchi, Saku-shi, Nagano 384-0412 JAPAN |

| Aichi | 9-10 Futano-cho, Mizuho-ku, Nagoya-shi, Aichi 467-0861 JAPAN |

| Osaka | 5-3-14 Nagatanaka, Higashi osaka-shi, Osaka 577-0013 JAPAN |

| Fukuoka | 2-2-17, Chojabarunishi, Kasuya-machi, Kasuya-gun, Fukuoka 811-2316 JAPAN |