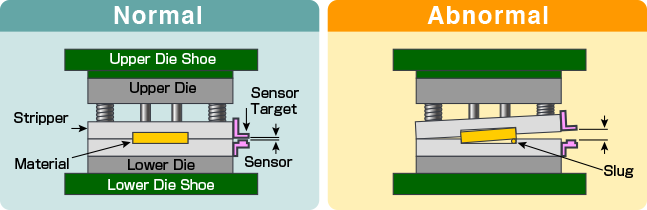

MICRON3 is a High Resolution Slug Detector for press operation that monitors the position of bottom dead center (BDC) every stroke using high performance proximity sensor. Setting the upper and lower monitoring limits based on the reference value calculated automatically by the sampling, when the detected value exceed the monitoring range, the device sends a stop signal immediately to the press machine. This device adapts Mean Value(Rolling Average) Monitoring Method and Absolute Value(Bench Mark) Monitoring Method, thus enable to perform more accurate and stable detection.

Features

- High accuracy with 0.1μm resolution.

- Simultaneously monitors rolling average and benchmark.

- Fault counter function incorporated.

- Automatic sensor calibration incorporated.

- Various sensors are provided.

Specifications

| Power Supply and Output section (only MIC3-B) |

Power supply | AC100-240V 50/60Hz |

|---|---|---|

| Power consumption | 15W or less | |

| Output contact | 1A, 1B (emergency output,auxiliary output) | |

| Output contact capacity | 250VAC or less, max.5A Cosφ=1 | |

| Detection section | No.of channels | 2 channles (Max.8, modification required) |

| Detection range | 0.8mm-1.8mm | |

| Repeatig accuracy | 1μm (0.1μm at high sensitivity) | |

| Monitoring range | Average ±99μm | |

| Sensor type | Proximity sensor for slug detector | |

| Display section | Display | 7-segment LED |

| Others | Backup | Semiconductor memory, Backup period: 10 years or more |

| Maximum speed | 2,400spm | |

| Temperature range | Working:-10°C-50°C(non freezing) / Storage:-20°C-75°C | |

| Humidity range | 10-85%RH (at wet bulb temperature of 29℃ or less, non condensation) |